Polini Thor 250 CDI Problem: A Comprehensive Guide to Troubleshooting and Solutions

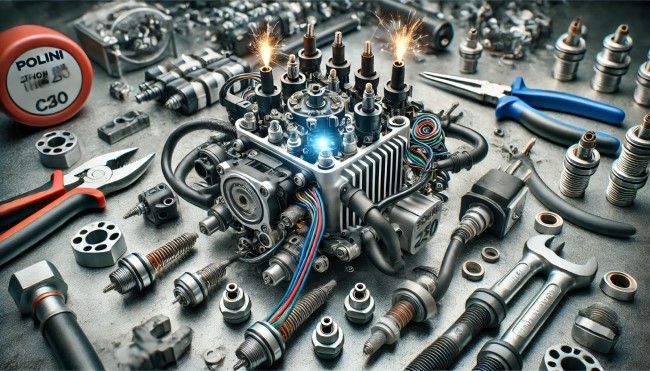

The Polini Thor 250 is one of the most popular paramotor engines on the market, admired for its power and performance. However, like any machine, it can encounter problems, particularly with its CDI (Capacitor Discharge Ignition) system. This article will delve into the most common issues related to the “Polini Thor 250 CDI problem,” offering solutions and guidance on addressing them. We will also explore topics such as the Polini Thor 250 Dual CDI No Spark, CDI Box, generic CDI options, Dual Coil No Spark, and CDI Pickup failures. Whether you’re a pilot or a paramotor enthusiast, this article will provide in-depth information and useful tips for keeping your Polini Thor 250 running smoothly.

What is a CDI System and How Does it Work?

The CDI system is responsible for generating the spark necessary to ignite the fuel-air mixture in the engine. It works by storing electrical energy in a capacitor and then discharging it at the right moment to the ignition coil, which then transfers the spark to the spark plug. A properly functioning CDI system ensures that the engine starts easily and runs smoothly.

However, when the CDI system malfunctions, the engine can suffer from misfires, loss of power, or even complete failure to start. Let’s explore some common CDI-related problems encountered with the Polini Thor 250 engine.

Common Polini Thor 250 CDI Problems

1. Polini Thor 250 CDI No Spark Issue

A common issue with the Polini Thor 250 is the “no spark” condition. When the CDI fails to generate the necessary spark, the engine won’t start, leaving pilots stranded or unable to take off. This problem often arises due to:

- Faulty Ignition Coil: The ignition coil can wear out or fail over time, leading to an inability to generate a spark. If this is the case, replacing the ignition coil is necessary.

- Corroded or Damaged Wiring: Wires connecting the CDI box to the ignition coil and spark plug can become corroded or damaged. Inspecting the wires and connectors for corrosion, breaks, or loose connections is crucial.

- Defective CDI Unit: A defective CDI unit can also result in a no-spark condition. Replacing the CDI unit is often the only solution in this case.

2. Polini Thor 250 Dual CDI No Spark

The Polini Thor 250 is available in a dual-spark version, which uses two CDI units to ignite two spark plugs simultaneously. This dual ignition system is designed to provide greater reliability and redundancy. However, it can also suffer from no-spark issues. In most cases, the problem can be traced to:

- Malfunctioning CDI Units: Both CDI units must function properly for the engine to run. If one of them fails, the engine might not start, or it may run poorly.

- Wiring Issues: Similar to the single CDI system, the wiring connecting the CDI units to the ignition coils and spark plugs should be inspected for corrosion, breaks, or loose connections.

- Pickup Coil Problems: The pickup coil is responsible for sending the timing signal to the CDI. If the pickup coil malfunctions, the CDI will not discharge the stored energy at the correct time, leading to a no-spark condition.

Polini Thor 250 CDI Box Overview

The CDI box, or control unit, is a vital component of the ignition system. It stores electrical energy and releases it to the ignition coil at the correct moment. The Polini Thor 250 CDI box is designed to withstand high temperatures and vibrations but can fail over time due to various factors, including:

- Heat Damage: Prolonged exposure to high temperatures can cause the internal components of the CDI box to degrade, leading to failure.

- Vibration: Paramotors experience significant vibration during operation, which can loosen connections inside the CDI box or cause components to wear out prematurely.

- Electrical Surges: Voltage spikes or surges can damage the CDI box, especially if the engine has been modified or is using aftermarket electrical components.

If the CDI box fails, the engine will not generate a spark, and replacing the CDI box is the only viable solution.

Generic CDI for Polini Thor 250

For those looking to replace a faulty CDI unit, there are generic CDI options available for the Polini Thor 250. While these generic options may be more affordable than OEM parts, they come with certain risks, including:

- Compatibility Issues: Not all generic CDI units are compatible with the Polini Thor 250. It’s crucial to ensure that the voltage and wiring configuration match the specifications of the original unit.

- Performance Problems: Generic CDI units may not perform as well as OEM parts, leading to potential issues such as misfires, poor fuel efficiency, or even engine damage.

It’s generally recommended to use OEM CDI units or high-quality aftermarket parts specifically designed for the Polini Thor 250 to ensure optimal performance and reliability.

Polini Thor 250 Dual Coil No Spark

In dual-coil configurations, the Polini Thor 250 uses two ignition coils to provide redundancy and improve spark reliability. If both coils fail to produce a spark, the problem could be related to:

- Coil Failure: Both coils may fail simultaneously due to wear and tear or electrical surges. Replacing the coils is necessary to restore proper engine function.

- Wiring Issues: As with single-coil configurations, wiring problems can prevent the coils from receiving the necessary electrical current. Inspect all wiring and connectors for damage or corrosion.

- CDI or Pickup Coil Failure: If the CDI or pickup coil malfunctions, the dual coils will not receive the signal to generate a spark, resulting in a no-spark condition.

Polini Thor 250 CDI Pickup Failure

The CDI pickup is a sensor that detects the position of the engine’s crankshaft and sends a signal to the CDI to release the stored electrical energy. If the pickup fails, the CDI will not release the energy at the correct time, resulting in engine misfires or no spark at all. Common causes of pickup failure include:

- Physical Damage: The pickup can be damaged by debris or engine components, leading to malfunction.

- Wiring Problems: Damaged or corroded wiring connecting the pickup to the CDI can prevent the signal from reaching the CDI unit.

- Wear and Tear: Over time, the pickup can wear out, especially in high-vibration environments like paramotors. Replacing the pickup is often necessary if it becomes worn or damaged.

Preventive Measures and Maintenance Tips for the Polini Thor 250 CDI System

To prevent CDI-related problems with your Polini Thor 250, regular maintenance and inspection are crucial. Here are some preventive measures you can take:

- Inspect Wiring Regularly: Check all electrical connections for signs of corrosion, damage, or looseness. Clean or replace any faulty wiring.

- Replace CDI Units and Coils as Needed: CDI units and ignition coils are consumable items that will wear out over time. Replace them at regular intervals to prevent sudden failures.

- Use the Correct Fuel: Ensure you’re using high-octane fuel as recommended by Polini. Lower-octane fuel can cause pre-ignition and other issues that can damage the CDI system.

- Protect from Moisture: Moisture can cause corrosion in electrical components, leading to CDI failures. Store your paramotor in a dry environment and avoid flying in wet conditions.

Conclusion

The Polini Thor 250 CDI system is a vital component of the engine’s ignition system, but like any mechanical part, it can encounter problems over time. From no-spark conditions to coil failures and wiring issues, understanding the common causes of these problems can help you maintain your engine and ensure it operates reliably. Regular maintenance, timely replacements of faulty parts, and using high-quality components are essential to keep your Polini Thor 250 in top condition.

By following the guidance in this article, you’ll be better equipped to troubleshoot and resolve CDI-related issues, ensuring that your paramotor is always ready for your next adventure.